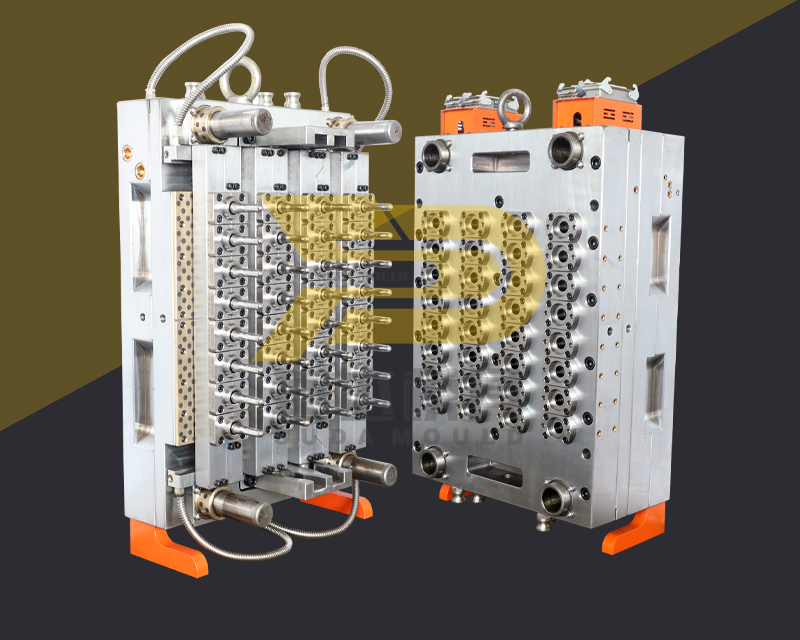

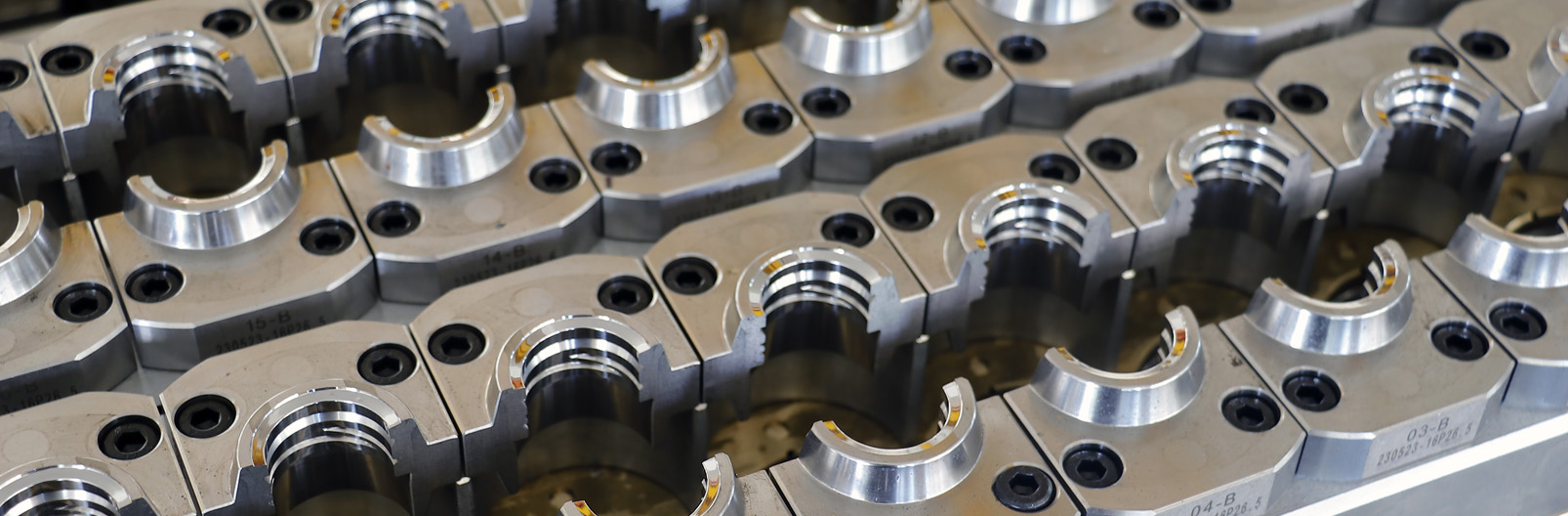

32-cavity hot runner PET preform mold (with valve gate)

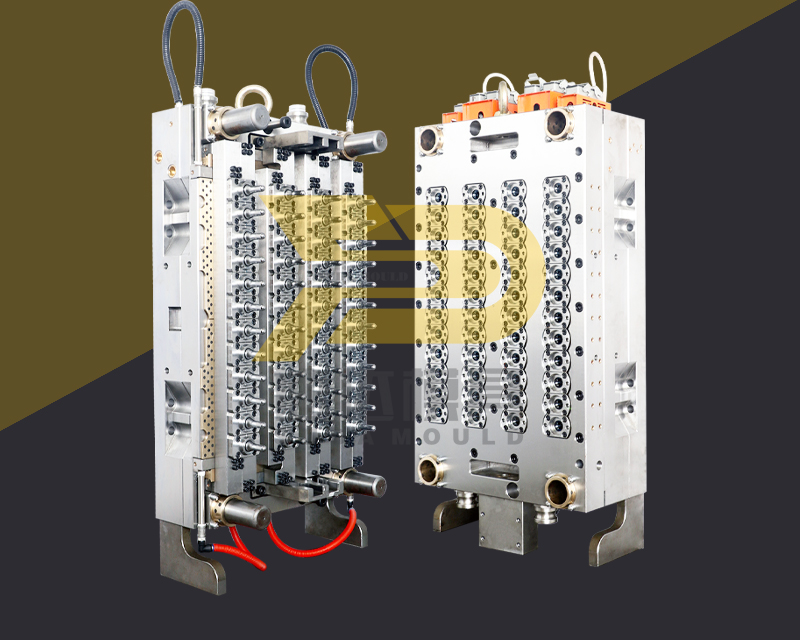

All Suda 32, 48, 72 cavity PET preform molds are precision designed to the highest quality standards.

We will work with you to ensure that you have the right PET preform injection molding system, molds and auxiliary equipment for your current and future needs.

Suda specializes in the production of 32, 48, 72 cavity PET preform molds. It has a group of experienced craftsmen, senior engineers and 3D experts, employs a number of technical committee members and senior professors in the mold industry as technical consultants, introduces various types of imported processing equipment and testing and measuring instruments, uses special drawing software for preform, sample design, trial mold manufacturing, and provides special technical training and good after-sales service.

32 cavity preform mold for PCO 1810 CSD bottle mouth preform, designed for CSD beverages, the mold has a balanced hot runner system and closed valve gate to ensure that there is no wire drawing on the injection gate of the preform. The cam roller design helps the operator save mold maintenance time. The PET preform mold is designed for Suda injection molding system. The preform weight is 25 g and the cycle time is 25 seconds using a common PET screw injection molding machine. With a 3-stage post-cooling system, the cycle time is 13 seconds.

Only focus on preform molds! High quality and efficiency of multi-cavity preform molds. PET molds specify 2-14/16/24/32/48/64/72/96/144 cavities, reliable PET mold supplier. 100% satisfaction. Factory direct sales.

From design considerations to material selection and manufacturing technology, every aspect is carefully examined to ensure optimal performance and durability. By mastering the superior technology of PET preform molds, manufacturers can meet the growing demand for quality packaging solutions and gain a competitive advantage in the market.

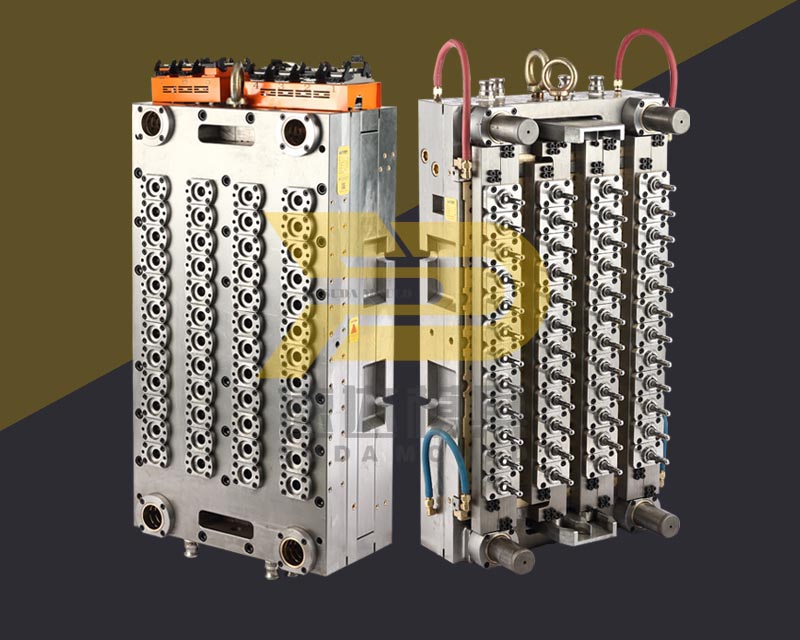

We are among the pioneers in the industry, engaged in offering 72Cavity Pet Preform Moulds to our revered customers. The offered Preform Moulds are extensively utilized in the production of a variety of PET bottles and enable uniformity & dimensional accuracy for them. Premium quality raw materials and sophisticated technology are applied in the manufacture of these Preform Moulds.

Features:

Precise design

Heat treated

Corrosion resistance

Specifications:

Shaping Mode: Plastic Injection Mould

Product Material: Steel

PET preform molds: From 1 cavity to 96 cavity

1.We are one of the most reliable companies in this domain offering PET Preform Mould with advanced mould design technology.

Multicavity: 1-8 cavity, 12 cavity, 16 cavity, 24 cavity, 32 cavity, 48 cavity, 56 cavity, 72 cavity and 96 cavity.

Neck finish:PCO, 1810,1881,30/25,29/25,38 ,ALASK, ROPP; Jar neck and others.

| Cavity Number | 22g Preform Length:94mm | 32g Preform Length:120mm | 42g Preform Length:130mm | |||

| Dimension(mm) | Weight(kg) | Dimension(mm) | Weight(kg) | Dimension(mm) | Weight(kg) | |

| 4(1*4) | 500*290*430 | 550 | 500*290*445 | 600 | 500*290*455 | 680 |

| 6(2*3) | 430*370*400 | 760 | 430*370*415 | 850 | 430*370*425 | 900 |

| 8(2*4) | 490*370*435 | 810 | 490*370*450 | 900 | 490*370*460 | 970 |

| 12(2*6) | 630*370*435 | 1020 | 630*370*450 | 1100 | 630*370*460 | 1180 |

| 12(2*8) | 750*370*480 | 1240 | 750*370*495 | 1350 | 750*370*505 | 1450 |

| 24(3*8) | 830*440*500 | 1880 | 830*440*515 | 1950 | 830*440*525 | 2060 |

| 32(4*8) | 830*580*515 | 2360 | 830*580*530 | 2250 | 830*580*545 | 2600 |

| 48(4*12) | 1065*580*525 | 2930 | 1065*580*540 | 3050 | 1065*580*555 | 3150 |

| 72(6*12) | 1140*830*560 | 4320 | 1140*830*575 | 4450 | 1140*830*580 | |

PET preform Mould Feature

1. Mould plates are 4G13 or P20 stainless steel with pre-hardening process. Core, cavity and neck screw are made of S136 high Strength, anti-corrosive stainless steel. Mould plate is completed by one-time processing to ensure the concentricity of moulding hole and guide bush, guaranteeing the compact structure of mould.

2. Spiral cooling design for each single core and cavity, it helps to lessen the cycle time, improving production efficiency and saving costs. Opening/closing pulling plate adopts bearing slide type to drop the preform with realiable structure. And it is a highly integrated process of slider, pushing plate and ejection. All sliding parts surface inlaid self-lubricating copper alloys to ensure low friction effecient and strong wear-resistant.

3. Self- lock individually for each cavity to guarantee high precision and less defect of the final preform production as well as convenient disassembly.

4. Off-center adjustment system to ensure preform thickness difference < 0.10mm. Adopting double cone positioning principle guarantees high manufacturing precision to ensure the product without appearing flash, different size, irregular and other defects.

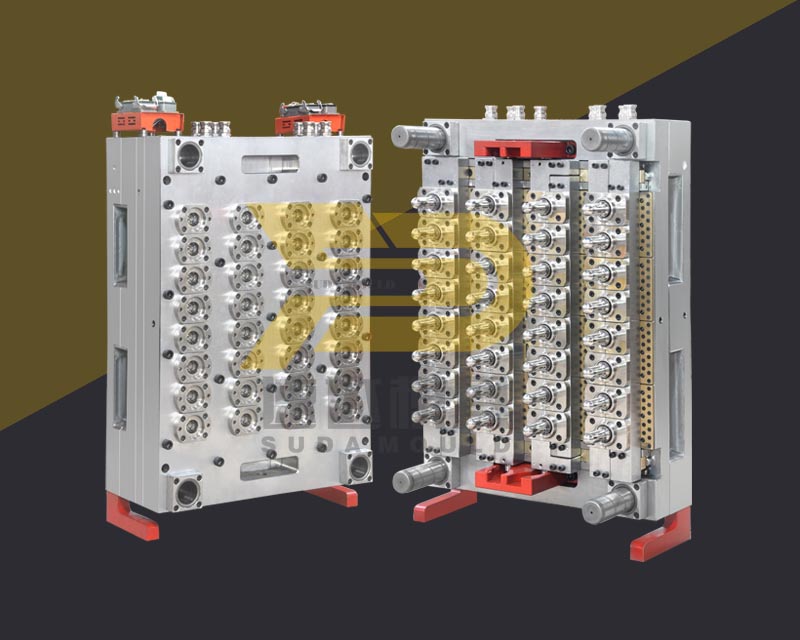

5. Experienced designers design preform mould with UG, Pro-E according to the clients sample; Preform thickness and height is reasonably and perfectly designed to ensure the final bottles weight light but feel hard.

6. Hot runner valve gate system is perfect used; No need to cut preform tail and it would save labor costs.

7. Hot runner system uses China advanced brand or imported hot runner system brand such as Yudo/Mastip/Hasco etc. Each cavity has independent temperature control and heater system. It will prevent the white defects on the preform and improve the qualtiy of plastic products.

8. Customer service: one year free warranty, life-long technical support service.

| Preform | Cavities | Structure | Dimensions | Weight | Array |

28/30mm caliber 15-35g | 4C | Needle valve | 420*260*450mm | 270kg | 1 |

| 6C | Needle valve | 530*260*450mm | 340kg | 1 | |

| 8C | Needle valve | 420*360*460mm | 380kg | 2 | |

| 12C | Needle valve | 530*360*460mm | 480kg | 2 | |

| 16C | Needle valve | 700*360*480mm | 660kg | 2 | |

| 20C pressure ports | Self-Locking | 820*340*370mm | 560kg | 2 | |

| 24C | Needle valve | 820*470*500mm | 1000kg | 3 | |

| 32C | Needle valve | 820*570*500mm | 1300kg | 4 | |

| 48C | Needle valve | 1094*620*587mm | 2200kg | 4 | |

| 72C | Needle valve | ||||

| 96C | Needle valve | 1250*1050*700mm | 5000kg | 6 |

| 38mm/64g | 6C | Needle valve | 480*400*533mm | 520kg | 2 |

| 8C | Needle valve | 550*400*533mm | 640kg | 2 | |

| 16C | Needle valve | 720*400*533mm | 840kg | 2 |

Oil bottle 46mm/90-110g | 4C | Needle valve | |||

| 6C | Needle valve | 530*420*550mm | 660kg | 2 | |

| 8C | Needle valve | 580*420*550mm | 730kg | 2 | |

| 12C | Needle valve | 720*370*550mm | 800kg | 2 |

| wide mouth 80mm/54g | 2C | Short self-locking | 350*280*380mm | 200kg | Side inclined guide pillar |

| wide mouth 100mm/69g | 4C | Short self-locking | 510*450*400mm | 500kg | Side inclined guide pillar |

| wide mouth 80mm/54g | 6C | Short self-locking | 570*410*400mm | 510kg | Built-in inclined guide column |

| wide mouth 120mm/60g | 8C | Short self-locking | 736*478*400mm | 780kg | Built-in inclined guide column |

| wide mouth 55mm/13g | 12C | Short self-locking | 800*320*330mm | 460kg | Built-in inclined guide column |